To equip the nation with human resources having Chemical Engineering expertise and concern towards the environment

The Department of Chemical Engineering owes its inception and its growth to its present state to the munificence and vision of our founder Chairman. This department was started in the year 2002.The department aims at nurturing chemical engineers with sound technical background and with a passion for sustainable development.

The department has well established State of the art laboratories to imbibe. Department uses latest instrument for analysis, like spectrophotometer, FTIR and modern equipment like centrifuges rotary drum driers and cyclone separator.

The department is well supported by faculty with diverse specialization like, bio fuels and biotechnology,Energy,Engineering and thermodynamics, petroleum processing and petrochemical, material science and technology. Two of the faculty holds Ph.D from leading institutions. Students project are published in leading research journals and our students have won laurels in extracurricular and co-curricular activities.

On the whole, the department strengthens its record day by day both in research and academics is bound to surpass its own achievement, and energy as a leading school for research and academics.

VISION OF THE DEPARTMENT

To equip the nation with human resources having Chemical Engineering expertise and concern towards the environment

MISSION OF THE DEPARTMENT

To nourish students in Chemical Engineering fundamentals.

To facilitate for continuous updating of their knowledge.

To enthuse the students to involve in interdisciplinary studies and research.

To inculcate values of ethics, leadership and professional integrity.

PROGRAMME EDUCATIONAL OBJECTIVES (PEOS)

Within first few years after graduation in Chemical Engineering at Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala Engineering College, Our graduates will,

Have the potential to work effectively as an individual and as well as in teams in the field of Chemical Engineering and allied disciplines.

Have the ability to pursue higher studies and research through continuous and lifelong learning.

Have engaged in their career development through entrepreneurial skills with high sense of social responsibility considering ethical, economical, environmental factors.

PROGRAMME OUTCOMES (POS)

PO1: Engineering knowledge:Able to apply the knowledge of mathematics, science, engineering fundamental, and an engineering specialization to the solution of Chemical engineering problems.

PO2: Problem analysis:Able to identify, formulate, research literature to analyse engineering problems & conclude using first principles of mathematics, chemical and engineering sciences.

PO3: Design/development of solutions:Design chemical engineering processes that meet the specified needs with the appropriate consideration for public health & safety, cultural and environmental considerations.

PO4: Conduct investigations of complex problems:Conduct research,analysis, synthesis and interpretation of data to provide valid conclusions.

PO5: Modern tool usage:Select and apply appropriate techniques, modern engineering and IT tools to predict and model complex engineering activities with an understanding of the limitations.

PO6: The engineer and society:Capable of applying broad reasoning by the contextual knowledge to assess societal, health & safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO7: Environment and sustainability:Understand the impact of the professional engineering solutions in societal and environmental contexts and demonstrate the knowledge of sustainable development.

PO8: Ethics:Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practices.

PO9: Individual and team work:Function effectively as an individual and as a member or leader in diverse teams and in multidisciplinary settings.

PO10: Communication:Communicate effectively with the community and with the society at large and design documentation, make effective presentations, and give and receive clear instructions.

PO11:Project management and finance:Demonstrate knowledge and understanding of the engineering and management principles and apply to work as a member in multidisciplinary environments.

PO12: Life-long learning:Recognize the need for life-long learning in the broadest context of technology change.

The people who are crazy enough to think they can change the world are the ones who do.

–Steve Jobs–

BOS I

The first Board of studies meeting was held on 24.08.2021 from 10.00 am to 12.10 pm through google meet to finalize the B.Tech. - Chemical Engineering curriculum for semester I to VIII and to finalise syllabi for the departmental courses offered in semester I, II, III.

The following members were present during the Board of Study meeting.

BOS II

The board of studies meeting II was virtually convened on 18.10.2022 using google meet platform to formulate the B.Tech. - Chemical Engineering curriculum for semester I to VIII and to finalise syllabi for the departmental courses offered in semester IV and V, professional electives offered in semester V and open elective courses offered to other departments.

The following members were present during the Board of Study meeting.

Chemical Engineering comprises the following laboratory courses

· Organic Chemistry Laboratory

· Fluid Mechanics Laboratory

· Particle Mechanics Laboratory

· Chemical And Technical Analysis Laboratory

· Heat Transfer Laboratory

· Process Control Laboratory

· Computational Programming Laboratory For Chemical Engineers

· Mass Transfer Laboratory

· Chemical Reaction Engineering Laboratory

Laboratory Name: ORGANIC CHEMISTRY LABORATORY

Lab In charge: Mrs. P. Bharani

The organic chemistry laboratory enables the students to understand the basic principles involved in analysis and synthesis of different organic derivatives.

Students Performing Analysis of Carbohydrate Experiment

Laboratory Name: FLUID MECHANICS LABORATORY

Lab In charge: Ms. M. Janani

Students Performing Packed Bed Experiment

The fluid mechanics laboratory is equipped with the following facilities to make the students understand the behaviour of fluids.

1. Venturimeter

2. Orifice meter

3. Vertical annular pipe

4. Helical coil and Spiral coil

5. Frictional losses through long horizontal pipes

6. Minor through long horizontal pipes

7. Centrifugal pump

8. Reciprocating pump

9. Packed bed column

10. Fluidized bed column

11. Bernoulli apparatus

12. Rotameter

Laboratory Name: PARTICLE MECHANICS LABORATORY

Lab Incharge : Ms. B. Manjupriya

II Year students Performing Ball mill Experiment

The particle mechanics laboratory enables the students to understand the characteristics of particle through techniques like size reduction, filtration, sedimentation, centrifugal settling processes with the help of the following equipments.

1. Sieve shaker

2. Jaw Crusher

3. Ball Mill

4. Roll Crusher

5. Drop Weight Crusher

6. Cyclone Separator

7. Elutriator

8. Leaf filter

9. Plate and Frame Filter Press

10. Rotary drum filter

Laboratory Name: CHEMICAL AND TECHNICAL ANALYSIS LABORATORY

Lab Incharge : Ms. M. Janani

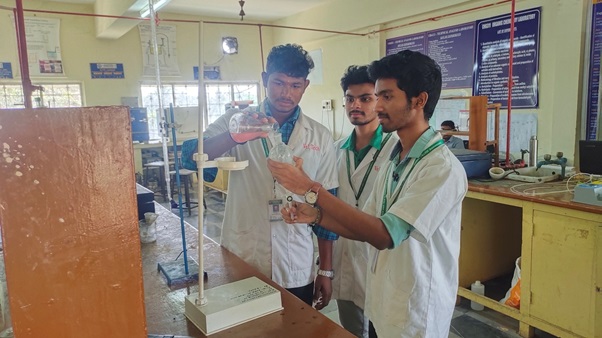

Students Performing Analysis of soap Experiment

Chemical and Technical analysis laboratory train the students on basic principles involved in estimation and characterization of industrially important materials. It has the following facilities

1. Hot air oven

2. Desiccator

3. Reflux Condenser

4. Pensky martens closed cup apparatus

5. Cleveland open cup apparatus

6. Cloud point apparatus

7. Aniline point apparatus

8. Saybolt Viscometer

9. Redwood Viscometer

10. Bomb Calorimeter

Laboratory Name: HEAT TRANSFER LABORATORY

Lab Incharge : Ms. S. Sunitha

The Heat transfer laboratory enables the students to develop knowledge on heat transfer processes like conduction, convection and radiation with the help of different heat transfer equipment

1. Double Pipe Heat Exchanger

2. Shell and Tube heat exchanger

3. Finned Tube Heat Exchanger

4. Composite wall apparatus

5. Stefan Boltzmann Apparatus

6. Natural convection set up

7. Forced convection set up

8. Open Pan Evaporator

9. Multiple effect evaporator

10. Helical Coil

11. Vertical Condenser

12. Agitated Vessel

13. Jacketed vessel

Laboratory Name: PROCESS CONTROL LABORATORY

Lab Incharge : Ms. N.U. Yuvasri

Process control laboratory guides the students to develop and use the right type of control dynamics process control under different operative condition using process simulation techniques.

1. U tube manometer

2. Interacting Tank and Non interacting tank

3. Open loop control system

4. Closed loop control system

5. ON/OFF controller

6. Pressure Tuner

7. Temperature Tuner

8. Proportional Controller

9. Flow Transmitter

10. Level Transmitter

11. Cascade control system

Laboratory Name: COMPUTATIONAL PROGRAMMING LABORATORY FOR CHEMICAL ENGINEERS

Lab Incharge : Mr.P. Vinosh Muthukumar

The Laboratory is facilitated with computers installed with various soft wares like Matlab, Aspen Hysys, Microsoft Excel etc. which enable the students to determine the numerical solutions for various chemical engineering problems.

Laboratory Name: CHEMICAL REACTION ENGINEERING LABORATORY

Lab Incharge : Mr.P. Vinosh Muthukumar

Chemical reaction engineering lab enables the students to understand the concept of different types of reactors under isothermal and non-isothermal conditions. It also imparts the knowledge of scaling up of laboratory reactions to large industrial scale.

1. Batch Reactor

2. Semi batch reactor

3. Plug flow reactor

4. Continuous Stirred Tank Reactor

5. Sono-chemical reactor

6. Packed bed reactor

7. CSTR in series

8. Temperature dependent kinetics set up

Laboratory Name: MASS TRANSFER LABORATORY

Lab Incharge : Mr.P. Vinosh Muthukumar

The Mass transfer laboratory would be able the students to determine important data for the design and operation of the process equipment like distillation, extraction, diffusivity and drying principles which are having wide applications in various industries.

1. Simple distillation setup

2. Steam distillation setup

3. Packed column

4. Liquid-liquid extractor

5. Tray dryer

6. Rotary dryer

7. Absorption column

8. Rotating disc contactor

9. Cooling tower

10. Ion exchange column

|

S.NO |

Laboratory name |

Major equipment details list |

Amount until now institution invested in this Laboratory(Rs.) |

|

|

Research Lab |

Fourier- Transform Infrared Spectroscopy |

8,50,000 |

|

|

Research Lab |

Gas Chromatography |

7,16,000 |

|

|

Research Lab |

Atomic Adsorption Spectroscopy |

5,52,000 |

|

|

Research Lab |

Double- Beam UV Visible Spectroscopy |

4,70,000 |

|

|

Research Lab |

Fermentor |

2,10,000 |

|

|

Research Lab |

Incinerator |

1,25,000 |

|

|

Research Lab |

Photo-Chemical Reactor |

1,13,400 |

|

|

Research Lab |

UV Spectrophotometer |

1,08,750 |

|

|

Research Lab |

Digital Spectrophotometer |

1,05,000 |

|

|

Research Lab |

Spectrophotometer |

99,500 |

|

|

Research Lab |

Deep Freezer |

70,800 |

|

|

Research Lab |

BOD incubator |

74,000 |

|

|

Research Lab |

COD Reflux |

45,430 |

|

|

Research Lab |

Flame Photometer |

39,600 |

|

|

Research Lab |

COD analyser |

34,500 |

|

|

Research Lab |

BOD Analyzer |

34,000 |

|

|

Research Lab |

Jar Test Apparatus (Flocculator) |

32,800 |

|

|

Research Lab |

Digital Oxygen Measurement |

22,900 |

|

|

Research Lab |

Nephelometry |

12,500 |

|

|

Research lab |

Colorimetry |

6,800 |

|

|

Mass Transfer Lab |

Ion Exchange Column |

1,53,600 |

|

|

Mass Transfer Lab |

Gas- Absorption Column |

1,42,000 |

|

|

Chemical Reaction Engineering Lab |

Sono Chemical Reactor |

1,17,600 |

|

|

Chemical Reaction Engineering Lab |

Plug Flow reactor |

26,000 |

|

|

Chemical Reaction Engineering Lab |

Continuous Stirred Tank Reactor |

28,800 |

|

|

Chemical Technical Analysis Lab |

Muffle Furnace |

62,730 |

|

|

Chemical Technical Analysis Lab |

Bomb Calorimeter |

34,000 |

|

|

Chemical Technical Analysis Lab |

Water Bath |

12,035 |

|

|

Chemical Technical Analysis Lab |

Hot-air Oven |

12,000 |

|

|

Organic Chemistry Lab |

pH meter |

11,580 |

Academic Year 2022-2023

Semester II

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

21CY24T |

Organic Chemistry |

|||||

|

2 |

21CH25T |

Principles of Chemical Engineering |

|||||

Semester III

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

21CH33T |

Chemical Process Calculations |

|||||

|

2 |

21CH34T |

Fluid Mechanics |

|||||

|

3 |

21CH35T |

Chemical Process Industries |

|

||||

|

4 |

21CH36T |

Constitution of India |

|||||

Semester IV

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

21CH42T |

Physical Chemistry |

UNIT -1 |

UNIT -2 |

UNIT -3 |

UNIT -4 |

UNIT -5 |

|

2 |

21CH43T |

Particle Mechanics |

|||||

|

3 |

21CH44T |

Chemical Engineering Thermodynamics I |

UNIT -1 |

UNIT -2 |

UNIT -3 |

UNIT -4 |

UNIT -5 |

|

4 |

21CH45T |

Instrumental Methods of Analysis |

|||||

|

5 |

21CH46T |

Environmental Science Engineering |

|||||

|

6 |

21CH47T |

Essence of Indian Traditional Knowledge |

|||||

Semester V

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

21CH51T |

Heat Transfer |

|||||

|

2 |

21CH52T |

Mass Transfer I |

|||||

|

3 |

21CH53T |

Chemical Reaction Engineering I |

|||||

|

4 |

21CH54T |

Process Instrumentation, Dynamics and Control |

|||||

Semester VI

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

CH8601 |

Chemical Reaction Engineering II |

|||||

|

2 |

CH8651 |

Mass Transfer II |

|||||

|

3 |

CH8602 |

Chemical Engineering Thermodynamics II |

|||||

|

4 |

CH8652 |

Process Engineering Economics |

|||||

|

5 |

CH8653 |

Process Instrumentation, Dynamics and Control |

|||||

Semester VII

|

S.No |

Subject Code |

Subject Name |

NOTES |

||||

|

1 |

CH8791 |

Transport Phenomena |

|||||

|

2 |

CH8701 |

Process Equipment Design |

|||||

|

.No |

Name of the Faculty |

Name of the Topic |

Date of launching the e-content |

Web Link to View |

|

1 |

Dr.B.Bharathiraja |

Pharmacokinetics of A drug |

12.04.2023 |

|

|

2 |

Dr.J.B.Veeramalini |

Closed Control system |

12.04.2023 |

|

|

3 |

Dr.A.Saravanaraj |

Carnot cycle and Carnot theorems |

12.04.2023 |

|

|

4 |

Mr.Vinosh Muthukumar |

Principle of distillation |

12.04.2023 |

|

|

5 |

Ms.B.Manjupriya |

Characterization of Particle |

12.04.2023 |

|

|

6 |

Mrs.P.Bharani |

Phase diagram for Binary solutions |

12.04.2023 |

|

|

8 |

Ms.M.Janani |

Infrared Spectroscopy |

12.04.2023 |

|

|

9 |

Ms.S.Sunitha |

Equipments used in Air pollution Control |

12.04.2023 |

|

|

|

Mrs.R.Ramya |

Principles of Chemical Engineering |

12.04.2023 |

|

|

10 |

Ms.N.U.Yuvasri |

Environment and Ecosystem |

12.04.2023 |

|

|

11 |

Mrs.V.Karpagam |

Profitability Analysis |

12.04.2023 |

|

|

12 |

Mrs.P.L.Sivayogavalli |

Religious and Philosophy of Medieval India - Bhakti Movement |

12.04.2023 |

|

Academic year 2024-2025 |

||||||

|

S.No |

Title |

Event Organizing @ |

Year |

Date |

Faculty/Student With Designation |

FDP/ Workshop /Seminar /Confrence /STTP |

| 1 | FDP on NEXT Gen Research Skills; AI Tools and Hands-on |

SSN College of Engineering, Chennai . |

2025-2026 |

30-06-2025 to 05-07-2025 |

Dr.Mary Nancy Flora Assistant Professor |

FDP |

|

Academic year 2024-2025 |

||||||

|

S.No |

Title |

Event Organizing @ |

Year |

Date |

Faculty/Student With Designation |

FDP/ Workshop /Seminar /Confrence /STTP |

|

1 |

Dual-Chambered Microbial Fuel Cell & Genetic Mutation Using Artificial Intelligence Tool for Bio-Hydrogen Production of Culture Chlamydomonas reinhardtii and Chlorella pyrenoidosa |

IIChE-CHEMCON 2024, NIT, Jalandhar |

2024-2025 |

27-12-2024 to 30-12-2024 |

Dr.J.B.Veeramalini Associate Professor Chemical Engineering Department |

Conference (IIChE) |

|

2 |

Comparative sorption capacity for the removal of Cr (VI) and Ni (II) from effluents using activated carbon produced from stems of Helianthus annuus and leaves of Cocos nucifera |

IIChE-CHEMCON 2024, NIT, Jalandhar |

2024-2025 |

27-12-2024 to 30-12-2024 |

Dr.A Saravana Raj Associate Professor Chemical Engineering Department |

Conference (IIChE) |

|

3 |

Comparative sorption capacity for the removal of Cr (VI) and Ni (II) from effluents using activated carbon produced from stems of Helianthus annuus and leaves of Cocos nucifera |

IIChE-CHEMCON 2024, NIT, Jalandhar |

2024-2025 |

27-12-2024 to 30-12-2024 |

Mr.Vinosh Muthukumar P Assistant Professor Chemical Engineering Department |

Conference (IIChE) |

| 4 | Design, Development and Performance Evaluation of Photocatalytic Membrane Reactor for Degradation of Recalcitrant Pollutants | Centre for Environmental Studies, Department of Civil Engineering, Anna University, Chennai. | 2024-2025 | 05.03.2025 |

Dr.Mary Nancy Flora Assistant Professor |

Workshop |

| 5 | Role of chemical engineering towards sustainable developmemt and atmanirbhar Bharat Title: Dual Chambered Microbial Fuel Cell & Genetic Mutation using AI tool for Bio-Hydrogen Production |

IIChE-CHEMCON 2024 NIT Jalandar |

2024-2025 | Dec- 27-30, 2024 | Ms.Swetha K |

International COnference |

| 6 | Dual Chambered Microbial Fuel Cell & Genetic Mutation for Bio Hydrogen production of culture chalmyo reimhardtii and chlorella pyrenoidosa | ASCENT 2025 | 2024-2025 | 20-03-2025 to 22-03-2025 | Ms.Swetha K | International COnference |

|

Academic year 2023-2024 |

||||||

|

S.No |

Title |

Event Organizing @ |

Year |

Date |

Faculty/Student With Designation |

FDP/ Workshop /Seminar /Confrence /STTP |

1 |

Membrane based Water treatment | Satyabama institute of Science and Technology |

2023-2024 |

1-2-2024 |

Mrs.Pl.Sivayogavalli, Assistant Professor Chemical Engineering Department |

Workshop |

| 2 | Membrane based Water treatment | Satyabama institute of Science and Technology |

2023-2024 |

1-2-2024 |

Mr.V.Dinesh, Assistant Professor Chemical Engineering Department |

Workshop |

| 3 | Membrane based waste Water treatment | Satyabama institute of Science and Technology |

2023-2024 |

1-2-2024 |

Mr.S.Sathish Kumar, Student Chemical Engineering Department |

Workshop |

| 4 | Membership: ISTE | Indian Society for Technical Education | 2023-2024 | Life Membership | Mrs.PL.Sivayogavalli, Assistant Professor | Membership |

| 5 | Membership: ISTE | Indian Society for Technical Education | 2023-2024 | Life Membership | Mrs.B.Manjupriya, Assistant Professor | Membership |

| 6 | Membership: ISTE | Indian Society for Technical Education | 2023-2024 | Life Membership | Mr. V.Dinesh, Assistant Professor | Membership |

| 7 | Membership: ISTE | Indian Society for Technical Education | 2023-2024 | Life Membership | Mr. M.Janani, Assistant Professor | Membership |

| 8 | Workshop - Aavishkar 2024 | Coimbatore Institute of Technology | 2023-2024 | 22-03-2024 |

Mr. Sathish Kumar S Student |

Workshop |

| 9 | Paper Presentation: Title : Comparative Sorption Capacity for removal of Cr(VI)&Ni(II) from Effiuients using activated-CO produced from Helianthus Annuusand Leaves for COCOS Nucifera | Hindustan Institute of Science and Technology, Coimbatore | 2023-2024 | 25-03-2024 |

Mr. Sathish Kumar S Student |

Paper Presentation |

Dr. J.B.Veeramalini

Head of the Department and Associate Professor

HOD MESSAGE

It is my pleasure and honour to welcome you to the Department of Chemical Engineering of Vel Tech High Tech Dr. Rangarajan Dr.Sakunthala Engineering College which is one among Top 10 Engineering Colleges in Tamil Nādu. The department was started in the year 2002 with the aim of nurturing Chemical Engineers with sound technical background with a passion for sustainable development. It has well established state of the art laboratories to imbibe and it is well supported by faculty with diverse specialization like Bio fuels and Biotechnology, Environmental Engineering and Thermodynamics, Petroleum Processing and Petrochemical, Material science and Technology. Our faculty is recognized for their research and educational impact through their experiential skills. They are members of a variety of professional organizations. Our department is exponentially growing by leaps and bounds and our impact in chemical engineering education and research is poised for continual growth in the years ahead.

We have well established state of the art laboratories to imbibe and it is well supported by faculty with diverse specialization like Bio fuels and Biotechnology, Environmental Engineering and Thermodynamics, Petroleum Processing and Petrochemical, Material science and Technology. To support the research activities, DST- SERB have sanctioned Rs.25 lakhs in 2018 under the young scientist scheme. The department has received grant of Rs.11, 10,000/- for of ASPEN PLUS and ASPEN HYSYS Simulation Software under AICTE-MODROBS Scheme.

Our department provides several skill developments training to students through “Activity beyond classroom” like value added courses, Placement training, Research oriented sessions etc. Students are encouraged to take up research projects as Mini-project work from their 2nd year through which they have published many research and review articles. They are also motivated to take up internships in various chemical and its allied industries during their vacation.

The department also organizes various Interactive lectures, FDP, Seminar, Alumni interaction, workshop by inviting Educationist and Technocrats from Core industries and Allied industries. We also organize several industrial visits in reputed chemical firms for our Students every semester to link classroom teaching with working chemical plant. Department fosters our students participation & guide them excelling in various events organized at IITs and other reputed institutions.

A strong positive reputation of the department pulls many more for campus recruitment together emphasis gatequalifying students. If you have further questions after vising our website which provides details of faculty members, research activities, research facilities and various student activities, please feel free to contact us on email address provided on faculty pages.

Best wishes,

Dr. J.B.Veeramalini

Head of the Department and Associate Professor,

Department of Chemical Engineering

Head of the Department: Dr.J.B.Veeramalini

|

S.NO |

STAFFNO |

NAME OF THE FACULTY |

DESIGNATION |

DOJ |

| 1 |

HTS 1393 |

Dr.VEERAMALINI.J.B |

PROFESSOR |

04-Jun-2018 |

|

2 |

HTS 697 |

Dr. SARAVANA RAJ. A |

ASSOCIATE PROFESSOR |

21-Feb-2011 |

|

3 |

HTS 1788 |

DR. MARY NANCY FLORA R |

ASSISTANT PROFESSOR |

28.11.2024 |

|

4 |

HTS 1838 |

DR. G. ARUMUGAM |

ASSISTANT PROFESSOR |

26.06.2025 |

|

5 |

HTS 1861 |

DR. BEEVI FATHIMA M T |

ASSISTANT PROFESSOR |

17.06.2025 |

|

6 |

HTS 1870 |

DR CHELLAMBOLI C |

ASSISTANT PROFESSOR |

01.07.2025 |

|

7 |

HTS 1875 |

DR. M.YUVARANI |

ASSISTANT PROFESSOR |

02.07.2025 |

|

8 |

HTS 1878 |

DR. NIVEDITA S |

ASSISTANT PROFESSOR |

08.07.2025 |

|

9 |

HTS 1888 |

DR. SARAVANA PANDIAN P |

ASSISTANT PROFESSOR |

30.07.2025 |

|

10 |

HTS 825 |

P.VINOSH MUTHUKUMAR |

ASSISTANT PROFESSOR |

21-Dec-2011 |

|

11 |

HTS 1561 |

JANANI M |

ASSISTANT PROFESSOR |

04-Dec-2021 |

|

12 |

HTS 1697 |

DINESH V |

ASSISTANT PROFESSOR |

16-Oct-2023 |

|

S.NO |

NAME OF THE STAFF |

DESIGNATION |

QUALIFICATION |

|

1 |

SATHISH E |

LAB ASSISTANT |

B.SC(BIO) |

|

2 |

APARNA U |

LAB ASSISTANT |

B.SC Biochemistry |

|

3 |

CHIRANJEEVI B |

LAB ASSISTANT |

B.SC Biochemistry |

External Academic Audit

|

1 |

Name of the event |

External Academic Audit |

|

2 |

Event scheduled Date & Time |

28/01/2025-09:30 AM to 03:30.PM |

|

3 |

Name & Designation of the Resource person |

Dr. Vinu RProfessorDepartment of Chemical Engineering |

|

4 |

Official Address of Resource Person |

Indian Institute of Technology, Madras. |

Maintained by VTHT Innovative IOT Club | Vel Tech High Tech, Chennai. All Rights Reserved.